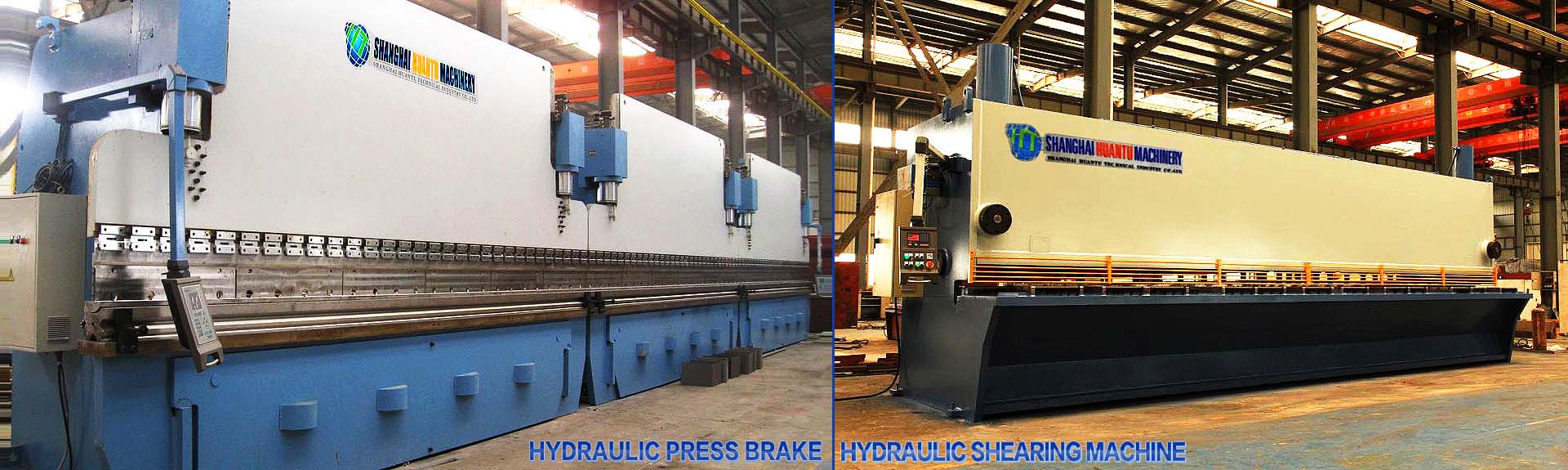

Streamlined design,high speed,high precision,high rigidity,CNC sheet metal press brake.

Electro hydraulic servo system,full loop controlling the synchronization of the upper beam.

Hydraulic compensation on crowning of worktable and deformation compensation of throat,ensuring good bending strength and precision.

Back gauge driven by digital AC servo motor,moved with long-stroke ball screw,linear guideway guiding.

Model and name of machine

Model: WE67K-160/3200(with DA52 CNC controller)

Name: CNC Electric-hydraulic servo (proportional) press brake

Quantity: One set

Control Technology

The synchronization of press brake adopt the technology of full loop electro hydraulic servo control,the positioning signal of the upper beam are feed back by raster (light-ruler) to CNC system and CNC system will check the opening size of synchronization valves,adjusting the inlet oil amount,to realize the synchronizing movements of the upper beam (Y1,Y2),and keep the worktable are always parallel situation. Following the situation of sheet metal to be bended,CNC system control automatically the amount of the crowning compensation of worktable to realize that angle being bended of workpiece can keep same along the full workpiece length.

Crowning Compensation

Crowning compensation system on worktable can make a workpiece having a same precision full along the length of the work piece. A crowning compensation system is composed of a group cylinders in line in worktable,which can from a relative movements of worktable,forming a curve needed of adding conves to worktable,to ensure unchanged the relative position to the upper beam of worktable after the worktable being under pressure. The crowning compensation amount is automatically calculated out by CNC system according to the worktable’s situation.

Typical aspect of sheet metal after bended.

Back Gauge

Upper tool clamping

All tools are full grinded and with hardening. Material: 42CrMo. Hardness: HRC42.

Valves (REXROTH,GERMANY)

Front Sheet—Support & Safety Guard

Key components of press brake

Valves: Rexroth,Germany

Oil seals: VALQUA,Japan.

Pump: CHENGJIE,Shanghai

Main Electrical components: Siemens,Germany

Main Motor: Siemens,Germany

Pressure gauge: Hawe,Germany

Oil filter: Compass,Taiwan,China.

Main specifications

Precision of machine

Ram of the machine (precision of X,Y1,Y2,Z and R Axis)

Position precision of the machine ±0.01㎜

Reposition precision of the machine ±0.01㎜

Working environment of machine

. Power supply: 380 V/3 phases/50 Hz

. Temperature: 5℃~+50℃

. Workshop environment: cleaning without dust

Main structure and performance of the machine

All parts of the machine use CAD/CAE/CAM software to design so as to ensure the strength and rigidity of each part.

This machine is hydraulic upper driven.

The machine is mainly comprised of machine frame,working table,ram,and main oil cylinder. The perfect design and manufacturing technology can ensure the manufacturing and using precision of machine. The technological procedures of main parts are as follows (please see Fig.1,2,3 separately for the structure stress design analysis of uprights,working table,ram)

Steel plate to warehouse→physical and chemical inspection→steel plate ball blasting (dustproof) processing→cutting through CNC flame cutting machine→cutting and processing to each welding junction plate→compound welding→air protection welding→vibration aging treament→processing through heavy-duty floor type boring and milling machine,heavy-duty gantry milling machine→fabrication.

The machine is the frame type structure,whose the installing faying surfaces of oil cylinders,lead rails,working table are processed at one time work holding through the technological procedures of heavy duty floor type boring and milling machine so as to ensure the parallelism and perpendicularity for each installing faying surfaces.

The lead rails of machine users the advanced self-lubrication material which does not need the regular lubrication and care.

The moving and positioning of left,right oil cylinder are controlled by CNC system (Y1,Y2),which is composed by the electrical hydraulic proportional valves,optical scales,CNC system. Each axis can be programmed individually,and can be worked under programming so as to get the higher moving and positioning precision when pressing the workpiece. Please see the Fig.4.

Fig.4

The machine can work normally under the eccentric loading state because of using the electrical-hydraulic proportional synchronization which can enhance the anti-torque,anti-eccentric-loading capacity extremely. The deformation of working table and ram is very little when pressing because of the higher designing rigidity of working table,uprights,cross-beam and ram. So,the work piece can get the perfect alignment and same pressing angle.

The machine has the motorized front feed mechanism,which is driven by variable-frequency motor.

The machine has the motorized back gauge,which is driven by variable-frequency motor.

The machine has the front and rear supporting frame,on which has the roller so as to feed conveniently.

The machine has the side out-feeding mechanism so as to effect the out-feeding conveniently.

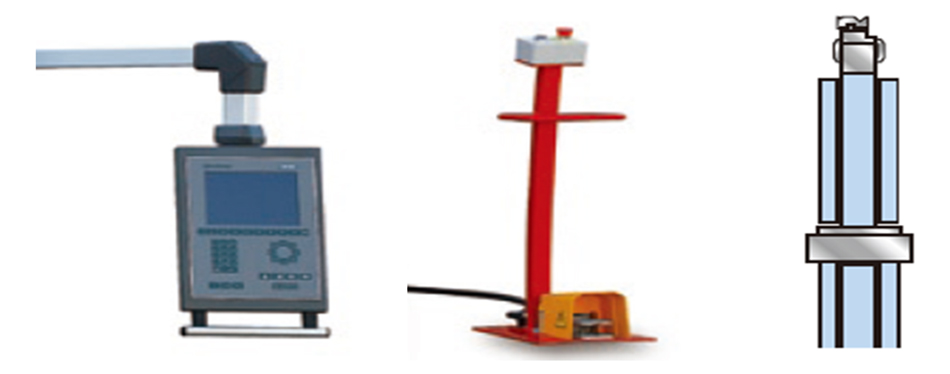

CNC system is the suspended operating station which can swing freely within the operating area,which also have the free movable foot/manual buttons.

Ⅵ.

CNC system

The DA-52 is an integrated CNC controller which offers all basic CNC control functions up to 4 axes for not only conventional press brakes but electro-hydraulic ones. The TFT-LCD display and the modern front panel layout guarantee a very user-friendly and easy to program controller.

Panel based housing makes it available to mount it directly onto electric cabinet or inside a pendent cabinet.

Special shortcut keys are designed for direct,rapid and easy programming.

Angle programming of Y axis,crowning compensation and force control are offered as standard configuration.

DA-52 offers a stable and reliable solution by taking advantage of the most up-to-date technology. USB interface is equipped to facilitate quick backup of product and tool data.

? Main Technical Specifications

? Parameter programming in one page

? 6.4" LCD,true-color,TFT display

? Crowning control

? Tool library

? Optional back gauges condo axis control

? USB interface

? Advanced Y axis control algorithm for controlling closed-loop valve and open-loop valve

? Servo,frequency inverter or AC motor control

? Panel based housing

Hydraulic system

Y1,Y2 axes use the electrical-hydraulic proportional servo valve technique. Hydraulic system is made in Rexroth,Germany. Please see Fig.10

Fig.10

The oil pump: internal gear pump,Chengjie,Shanghai.

The dynamic seal rings for main oil cylinder is made in VALQUA,Japan,which have the perfect sealing effect and long life.

The oil level can be displayed clearly by the oil level meter set on oil tank,which has the oil filter mechanism and blocking alarm function.

Extra loading overflow protecting function on hydraulic system.

Main components list

Model List: